We use cookies, including cookies from third parties, to enhance your user experience and the effectiveness of our marketing activities. These cookies are performance, analytics and advertising cookies, please see our Privacy and Cookie policy for further information. If you agree to all of our cookies select “Accept all” or select “Cookie Settings” to see which cookies we use and choose which ones you would like to accept.

In the last blog, we illustrated the working mechanism of a rotary through a single rotary compressor.

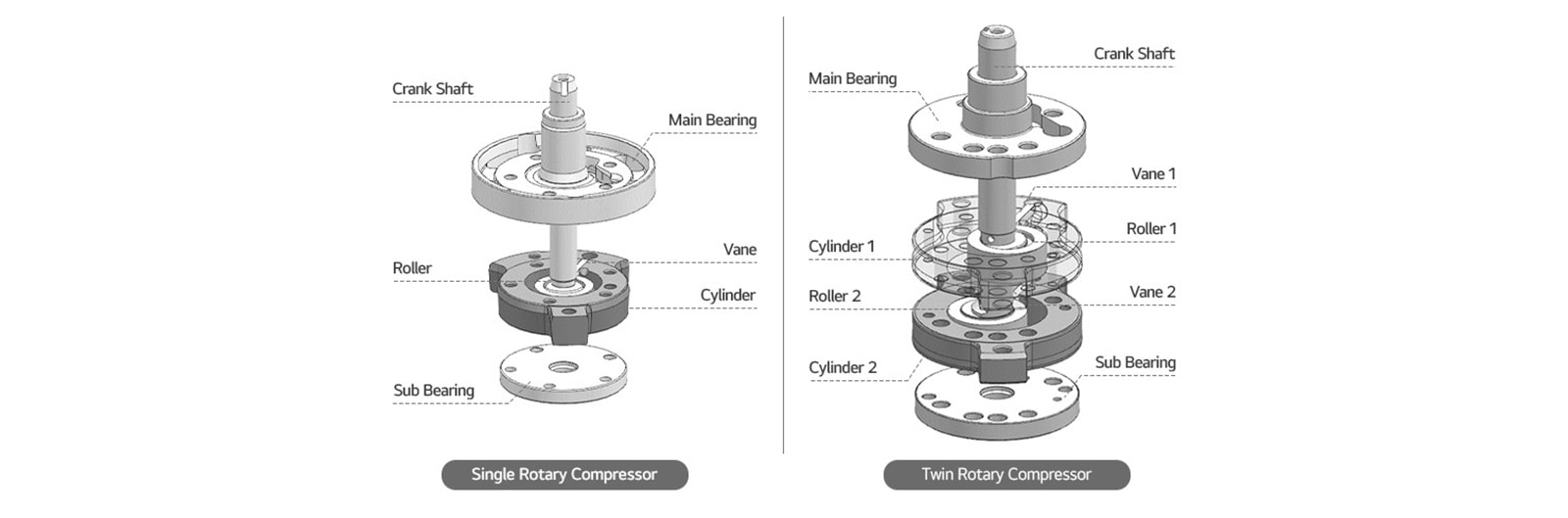

‘Single’ in a single rotary compressor refers to one compression chamber in the compressor. But can a compressor only have one compression chamber? The answer is— no.

A compressor can also have two compression chambers; the most common example is a twin rotary compressor. Twin rotary compressors are as widely used in heat pump dryers, humidifiers and other home appliances, as the single rotary compressor.

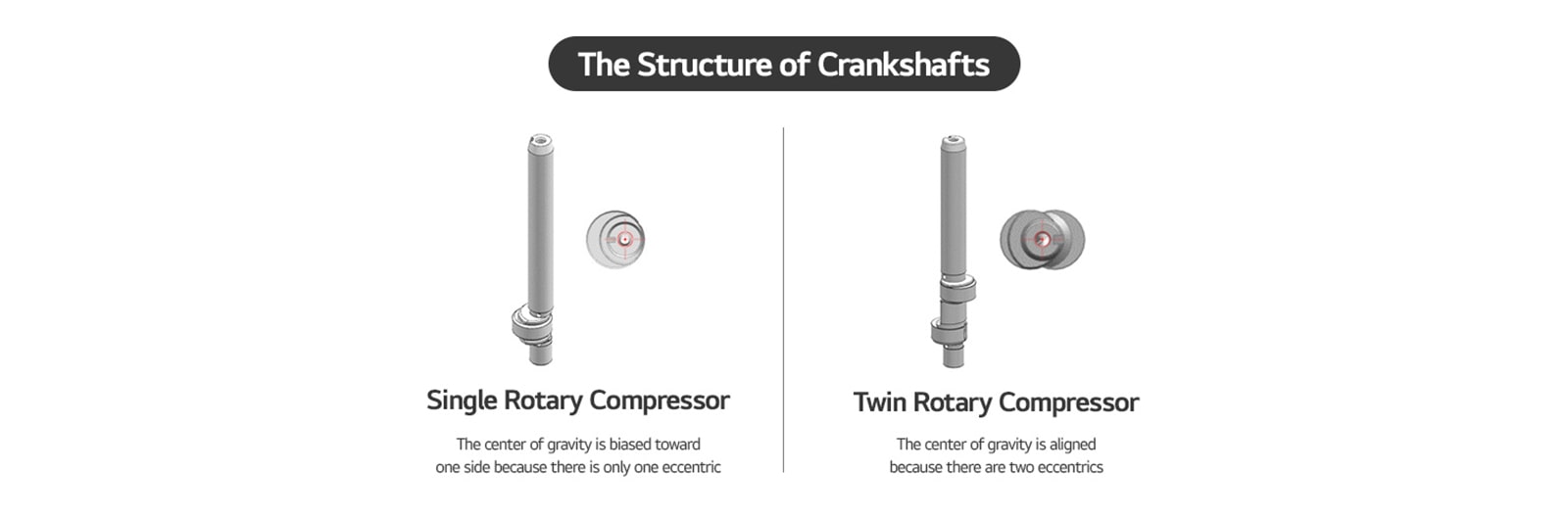

Let’s take a look at the operation mechanism of the twin rotary compressor consisting of two compression chambers meaning two cylinders.