We use cookies, including cookies from third parties, to enhance your user experience and the effectiveness of our marketing activities. These cookies are performance, analytics and advertising cookies, please see our Privacy and Cookie policy for further information. If you agree to all of our cookies select “Accept all” or select “Cookie Settings” to see which cookies we use and choose which ones you would like to accept.

LG Electronically Commutated Motor for HVAC Applications

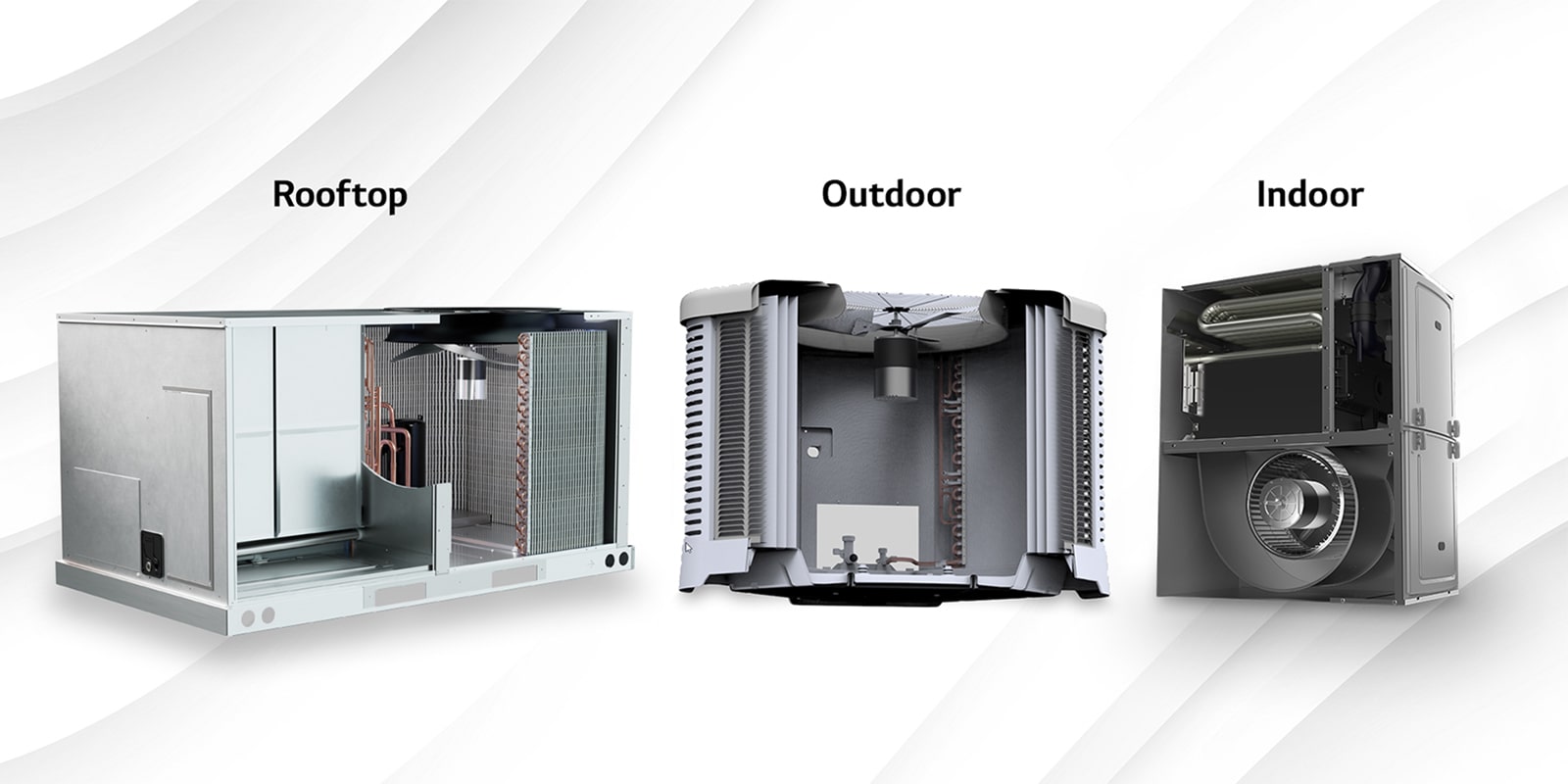

The LG EC Motor for HVAC applications has been launched and is available for OEM and field replacement opportunities. The EC Motor boasts a capacity range of 1/3 to 1HP for installation into a variety of HVAC components ranging from condensers, heat pumps, air handlers, furnaces and other air-related ventilation accessories..

As always, LG has maintained existing specifications to allow for maximum compatibility in the field or on the production floor. With indoor and outdoor models available, both provide a constant airflow that allows for better efficiency and comfort than traditional on/off units.

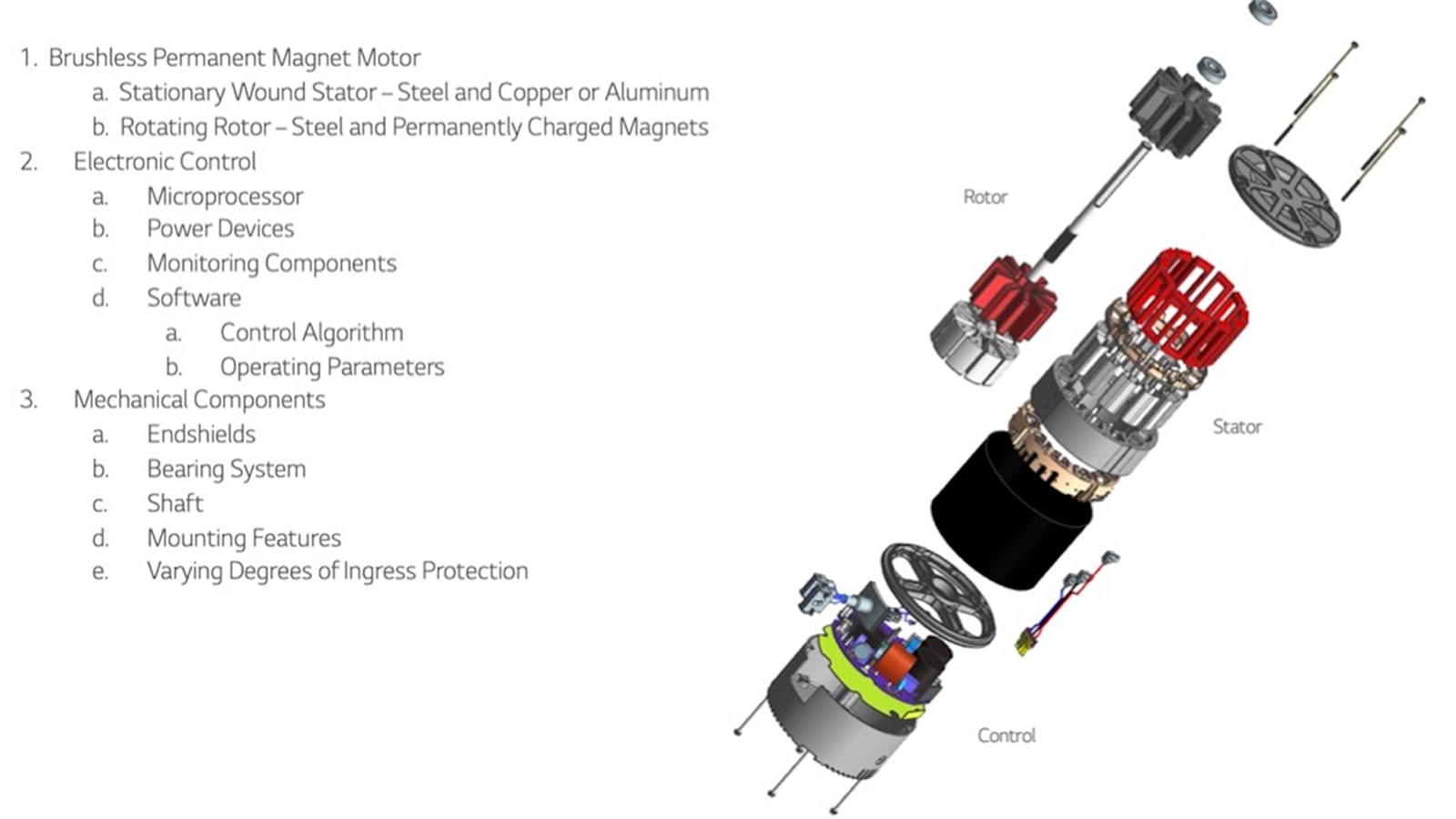

In case you’re not familiar with Electronically Commutated Motors, let’s review their internal components, how they work and their advantages for HVAC applications.

Internal Structure

How They Work

EC motors self regulate and make adjustments based on changes within the system, they do this by:

1. Rotor Position and Speed

- Sensorless controls utilize the Back Electromotive Force (BEMF) produced by the rotor moving past stator teeth to monitor rotor speed and location

- Sensored controls use special hardware (hall sensor, encoder etc.) to track the rotor’s speed and location

2. Motor Torque

- Specialized monitoring components in the control along with control algorithms determine a motor’s torque

3. Constant Airflow

- Specialized algorithms, with coefficients developed through testing a motor in a specific unit, compare and adjust motor speed and torque to maintain a constant airflow across varying ranges of static pressure.

Advantages

The LG EC Motor has been developed with several improvements over an Induction PSC motor, which has traditionally been used in HVAC systems, these include:

1. Noise Reduction

- Once powered, a PSC outputs a tremendous amount of unnecessary starting torque and current, then rushes to a designed speed

- ECMs employ a soft start and can be programmed with variable time to reach different speeds

- This results in reduced noises from ductwork or outdoor condenser and prolongs the life of the motor’s bearing system

2. Variable Speed and Programmable

- PSCs can be designed with multiple speeds, but lacks efficiency

- ECMs can be programmed with up to 32 different speeds via tap settings, and can be fully variable with PWM communication or other fully communicating inputs

- In some systems there can be field adjustments made to provide further customization to match the home’s design

3. Constant Airflow

- Maintaining a constant or circulating airflow in a home is ideal even between conditioning cycles

- Improved filtration and other health benefits

- Better maintains a home’s temperature.

- PSCs are capable of providing a constant fan operation, but more susceptible to changes in static pressure.

- ECMs increased efficiency over PSC technology, reduces utility costs

4. Efficiency

- Typical PSCs operate at peak efficiencies of 55-65%

- Typical ECMs operate in the efficiency range of 75-80%, with peak efficiency over 85%

- In cycle mode, ECMs offer a 25% improvement in efficiency

- In continuous fan mode, the efficiency can jump up as high as 75%

- Furnace/Air Handler annual energy savings: over 800kWh

Today and Tomorrow

Seasonal Energy Efficiency Ratio 2 (SEER2 2023)

- DOE regulations took effect January 1, 2023

- Introduced new M1 testing procedures and rating minimums in the SEER2, EER2, and HSPF2

- New and higher rating minimums require improved compressor technology and high efficiency multi-speed fan motors

Future Regulations - HVAC industry and regulators push for smarter and more efficient systems

- ECMs will continue to grow and expand capabilities to meet their demand

- ECMs adaptability makes them ideal air moving solutions

All these improvements mean higher customer satisfaction, better reliability and a partner in LG that is focused on providing quality components for the present and future.

"The information contained in the article is released by LG Electronics and may not be used for personal work. It may not be copied, reproduced, modified, decompiled, or reverse-engineered into any other work without prior permission from LG Electronics."

*Products and solutions may vary according to country and operating conditions.

Please click the 'INQUIRY TO BUY' banner below to contact your local LG office for further information.

- PreviousExplore Inverter Compressors with LG22/09/2023

- Next

The URL has been copied to the clipboard.