-

The arrival of COVID-19 and its impact on our lives has stressed the importance of air quality. The trend to improve indoor environments not only relates to comfort and convenience but also takes indoor air quality into consideration. Air quality is measured by the concentration of pollutants in the air such as gases, dust particles and microbes. According to ASHRAE 62.1, if the concentration of these pollutants in a space exceeds a certain level, the air quality is considered poor and may negatively affect the occupants. Thus, solutions to control these concentrations are essential.

LG provides various solutions for air quality control from stand-alone air purifiers to air purification kits for VRF and single/multi split cassette-type indoor units (except the 2-way cassette).

The UVnano Filter Box is a new option for Mid Static Duct units (M1, M2, M3 Chassis) that is installed at the return air side of the unit and aims to clean indoor air and improve air quality. The new UVnano Filter Box is expected to be launched globally by October of this year. The features of the new UVnano Filter Box will be introduced in this article.

-

Components and Structure of the UVnano Filter Box

The filter box consists of three main components; pre-filter, UVnano (UVC LED), and MERV 13 filter (ePM1 50% filter). There are 2 of each component and they are accessible either from the side or the bottom of the unit.

-

1. Pre-Filter

The pre-filter is the first component and it traps larger dust particles. They prevent the MERV-13 filter from getting clogged with larger particles so that it can filter smaller pollutants more efficiently. The pre-filter doesn’t need replacement and can be washed and re-used.

-

2. UVnano (UVC LED)

The second component is the UVnano LEDs. These UV LEDs shoot UVC (or ultraviolet type C) beams of light on the pre-filter and disinfect it. The LEDs are tilted with an angle to shoot in the direction of the pre-filter, which is placed in front of the MERV-13 filter. The UVnano has a certified 99.99% sterilization capability against bacteria and viruses parasitized on bacteria and it can be used semi-permanently without needing to be replaced.

-

3. MERV 13 Filter (ePM1 50% Filter)

The inner component of the filter is a 2-inch thick MERV 13 filter. The filter has an ISO 16890 classification of ePM1 50%. In other words, the filter can trap at least 50% of the PM1 dust particles in the air passing through it. Particles as small as 0.3μm in diameter can be sufficiently trapped, cleaning and providing healthier air indoors. According to ASHRAE recommendations, MERV 13 is the minimum filter grade for non-healthcare facilities to reduce airborne infectious aerosol exposure. The filter is replaced after 960 hours of operation. The user is notified of the replacement time through an alarm from the wired remote control.

-

More on UVnano (UVC LED)

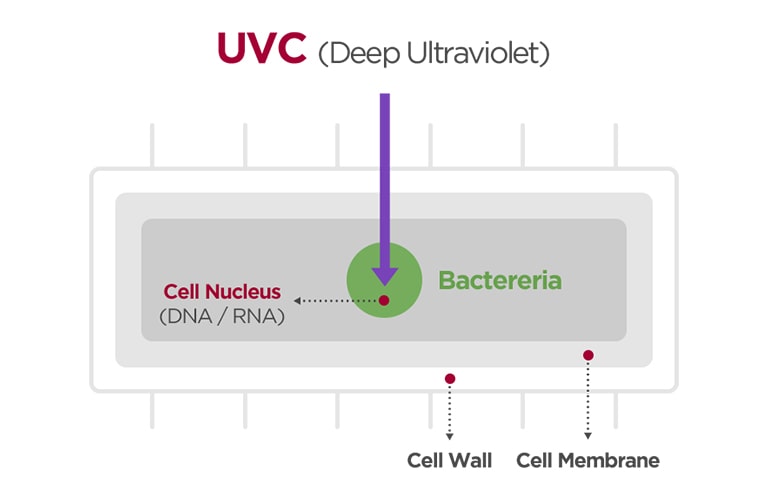

UVC represents the shortest range of ultraviolet light that ranges between 100 ~ 280 nm. The other two types of ultraviolet light are UVA and UVB and they range between 315~400nm and 280~315, respectively. Unlike these two types, UVC is completely absorbed by the ozone layer in the atmosphere and it is germicidal. It can disrupt micro-organisms’ ability to reproduce by causing chemical changes in the nucleic acids that form their RNA and DNA.

In bacteria, the UVC penetrates the cell wall and membrane and reaches the nucleus to stop the cell division function and prevent proliferation. According to the US FDA (Food & Drug Administration), UVC radiation has effectively been used for decades to reduce the spread of bacteria, such as tuberculosis.

-

In addition, UVC has been shown to destroy the outer protein coating of viruses parasitized on bacteria. This effect ultimately leads to the inactivation of the virus. However, currently, there is limited data published about the wavelength, dose, and duration of UVC radiation required to inactivate the particular viruses.

-

Certified Performance

1.UVnano (UVC LED)In order to verify the performance of UVC LED, two types of tests were carried out. The first one was to verify bacteria sterilization performance, and the other one was to verify sterilization of viruses parasitizing on bacteria. The tests are conducted in accordance with TUV Rheinland Standard.

In the first test, three types of bacteria were cultured on 6 membranes. They were, then, fixed on the pre-filter as a setup for the test. After that, the UVC LEDs were implemented as shown in the table below:

-

The TUV verification report shows that the UVC LED has a 99.99% sterilization performance on each type of cultured bacteria at the measuring points. This result would be different in practical usage conditions of an air conditioning system considering the airflow rate and other factors.

Similarly, in the second test, a virus was prepared and the host bacteria were cultured. 6 samples were prepared and attached to the pre-filter and the UVC LEDs were implemented in the same way as in the previous test. The test was conducted three times to confirm the results. And the results at each measuring point for the three test runs showed a virus sterilization performance of 99.99% as the TUV Rheinland report shows.

-

2.MERV 13 Filter (ePM1 50% Filter)

According to ASHRAE recommendations, the risk of infection per high filter grade can be improved slightly by increasing the ventilation rate. And with MERV 13, Bacteria and smoke can be removed, in addition to PM1 at an efficiency of at least 50%. Test results for filters’ ability to reduce infection risks with proper ventilation rates show that MERV 13’s risk of infection rate at no ventilation is slightly higher than that of HEPA filters. However, with ventilation rates at more than once per hour, this small gap can be covered.

With improved filtration (MERV 13 or higher), increasing ventilation provides a negligible contribution to the removal of bioaerosols from indoor air. Therefore, designing for high filtration and ventilating based on ASHRAE 62.1 is recommended to save energy and operating costs.

Note: MERV 13 filters cause a pressure drop that can be compensated for by adjusting the E.S.P value of the duct unit. For further details, please refer to the PDB and standard proposal.

-

MERV 13 Filter and Limiting Spread of Infections

MERV 13 filters have a more than 90% trapping efficiency when viruses spread in droplet form. Usually, normal activities such as coughing, speaking and even just breathing release droplets that vary in size from less than 1μm up to 10μm. Viruses on their own are very small in size, but they stick easily to these droplets which, in turn, are captured efficiently by MERV 13 filters.

(ASHRAE-based Measured [left] and Calculated Overall [right] Results)

-

Specifications

There are three filter box models to match the dimensions of the mid-static duct chassis. For further details regarding the available model’s specifications, please refer to the indoor unit’s Product Data Manual available on the Global B2B Partner Portal. http://partner.lge.com/global/index.lge

Please click the 'INQUIRY TO BUY' banner below to contact your local LG office for further information on solutions and products.