We use cookies, including cookies from third parties, to enhance your user experience and the effectiveness of our marketing activities. These cookies are performance, analytics and advertising cookies, please see our Privacy and Cookie policy for further information. If you agree to all of our cookies select “Accept all” or select “Cookie Settings” to see which cookies we use and choose which ones you would like to accept.

Chillers are the unsung heroes of modern HVAC systems, working behind the scenes to ensure efficient temperature control across various environments—from large office buildings to industrial plants. But how do we ensure that these intricate machines meet the highest performance and reliability standards?

LG HVAC Solution’s thorough chiller inspection process demonstrates the importance we place on inspections and how we carry out our unique inspection procedures. In this article will explain why this process is crucial and how it reflects our commitment to quality and customer satisfaction.

01 Why Chiller Inspections Matter?

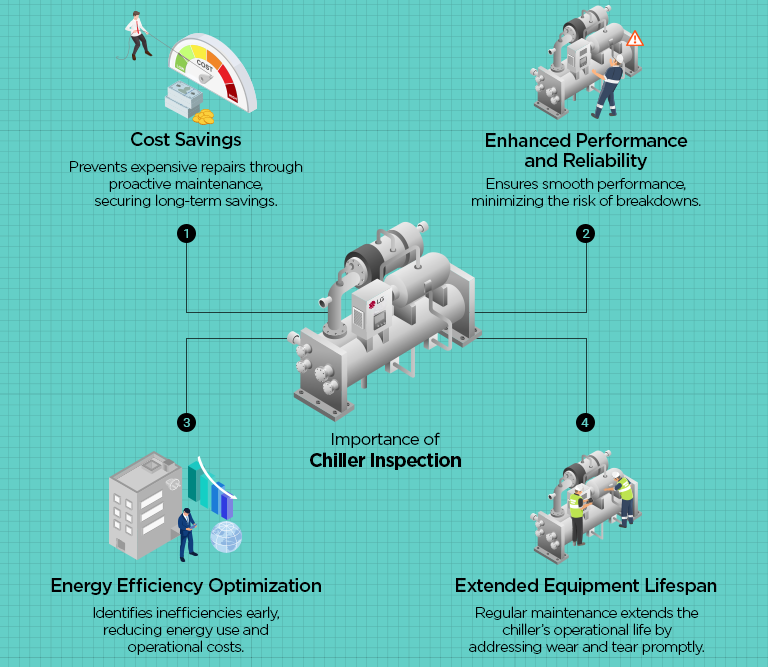

Chiller inspections are vital for ensuring the efficient, reliable, and safe operation of HVAC systems. Before leaving our facility, each chiller undergoes a thorough inspection process to guarantee optimal performance and long-term reliability.

These tests are essential, as chillers operate under varying conditions, and even minor inefficiencies can lead to increased operational costs and downtime. Regular inspections detect potential issues early, ensuring smooth operation in real-world conditions while optimizing energy efficiency and extending the chiller's lifespan.

Furthermore, they ensure compliance with safety standards, preventing accidents and promoting sustainability. Overall, routine inspections are key to maintaining high performance, operational stability, and long-term cost savings.

Chiller Inspection Importance: Reduced Costs, Optimized Performance, Extended Lifespan

02 A Step-by-Step of LG’s Chiller Test of Honor

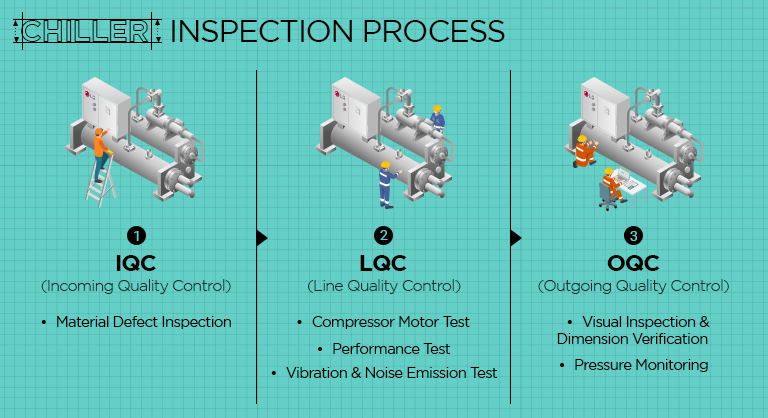

Chiller Inspection Steps: Material, Compressor, Performance, Visual, Pressure

STEP1: IQC (Incoming Quality Control)

This phase focuses on inspecting raw materials and components before they enter the production process to ensure they meet quality standards.

a. Material Defect Inspection

Components such as steel plates, flanges, and heat exchangers are inspected for chemical composition, electrical charge, and any defects. This ensures that only top-grade materials are used, forming the foundation for a durable and reliable chiller.

STEP2: LQC (Line Quality Control)

LQC ensures that quality is maintained during the production process, checking key components and testing performance as the chiller is being assembled.

a. Compressor Motor Test

The compressor motor undergoes a thorough inspection for accurate dimensions, internal cleanliness, and vibration levels. These checks guarantee that the motor performs efficiently without issues like rust or mechanical imbalance.

b. Performance Test

Engineers test critical aspects of performance, including water flow, temperature control, and power distribution. Cooling capacity and COP are measured to ensure that the chiller performs efficiently and meets expected standards.

c. Vibration & Noise Emission Test

Vibration and noise levels are tested to ensure minimal disturbance during operation. Engineers measure vibration at key points and assess noise emissions to confirm that the chiller runs smoothly and quietly, meeting the required noise level standards for each country. This ensures improved durability and suitability for noise-sensitive environments like offices or hospitals.

STEP3: OQC (Outgoing Quality Control)

This final phase verifies that the finished product meets all quality standards before it is delivered to the customer. It ensures there are no defects and that the product matches customer specifications.

a. Visual Inspection & Dimension Verification

After performance testing, engineers inspect all components for physical defects such as rust, cracks, or paint flaws. They also verify that the chiller’s dimensions precisely match the customer-approved design. These checks ensure the unit is free from visible defects and ready for smooth installation.

b. Pressure Monitoring

Hydrostatic and pneumatic pressure tests are conducted to ensure key components such as condensers and evaporators are free from leaks and can withstand operational pressures. This final step guarantees system reliability under real-world conditions.

03 LG HVAC: Advanced Technology in Chiller Inspection & Certified Quality Assurance

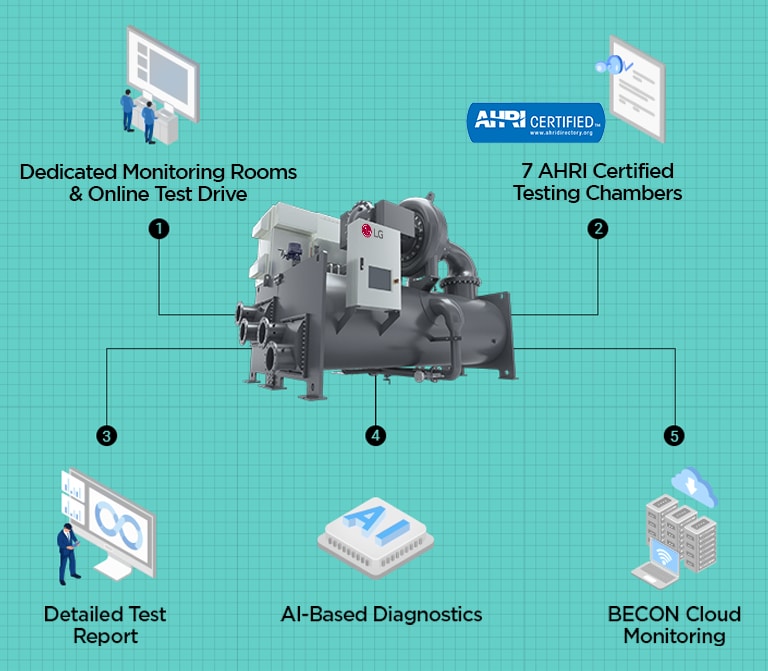

Chiller Inspection and Maintenance: Online Test Drive, AI-Based Diagnostics

LG HVAC ensures top-tier chiller quality through a thorough inspection process using 7 AHRI Certified testing chambers, consistently passing post-examinations for seven years. These chambers simulate real-world conditions, verifying each chiller’s performance, efficiency, and durability to meet industry standards.

Our advanced process combines AI-based diagnostics and BECON cloud monitoring for early fault detection and long-term reliability. Customers can oversee their chiller's test run via dedicated monitoring rooms or remotely through online test drives, ensuring complete transparency.

After testing, clients receive a detailed test report, covering all performance and efficiency metrics. This comprehensive inspection ensures that every chiller is thoroughly tested, providing customers with a reliable, high-quality product.

LG HVAC is committed to delivering high-quality chillers through our thorough external inspection process, ensuring each unit meets stringent performance and reliability standards. This dedication assures customers that they are receiving a top-tier product that will operate efficiently and effectively, providing long-term value and peace of mind.

Related Articles

More about LG HVAC

* Products and solutions may vary according to country and operating conditions.

Contact Us

Please contact us for more information, and we will get in touch with you soon.