We use cookies, including cookies from third parties, to enhance your user experience and the effectiveness of our marketing activities. These cookies are performance, analytics and advertising cookies, please see our Privacy and Cookie policy for further information. If you agree to all of our cookies select “Accept all” or select “Cookie Settings” to see which cookies we use and choose which ones you would like to accept.

In the vast world of HVAC systems, chillers play a pivotal role in ensuring our spaces remain cool and comfortable. These powerful systems are what’s behind the serene ambiance of large buildings, industrial facilities, and various other applications. But what exactly are chillers, and how do they function? Dive with us into the intricacies of chillers, as we unravel their types and the components that make them tick, all under the trusted banner of LG.

What is a Chiller?

An HVAC chiller is a sophisticated cooling system designed to remove heat from a liquid, typically water, and then circulate the chilled liquid through a building or facility to absorb heat. Essentially, it's the backbone of many large-scale air conditioning systems, ensuring spaces remain cool and comfortable. Chillers work by using a refrigeration cycle, where they transfer heat from the liquid to the ambient air or to a cooling medium, such as water. Their versatility makes them ideal for various applications, from cooling commercial buildings to facilitating industrial processes.

How do Chillers Work?

Chillers work based on the principles of thermodynamics and the refrigeration cycle. They are designed to remove heat from a specific space or process and transfer it to another location. The refrigeration cycle is a four-step process:

Step 1 - Compressor

A compressor compresses the refrigerant, which causes it to heat up and become a gas.

Step 2 - Condenser

The hot refrigerant gas is then passed through a condenser, where it cools and condenses into a liquid.

What’s the Difference Between a Chiller and a Chilled Water System?

A chiller is a device that removes heat from a liquid, typically water, by using a refrigeration cycle to transfer the heat to ambient air or a cooling medium, such as water, which is then used for cooling purposes.

While a chilled water system refers to the entire cooling system that circulates the chilled water, through a series of piping, pumps and coils to absorb heat from the air in the building or facility. The chilled water then returns to the chiller, where it is cooled again and the cycle repeats. Chilled water systems are a very efficient way to cool large spaces, and they are used in a wide variety of commercial and industrial applications. Imagine a chiller as a water cooler. The water cooler chills the water and then dispenses it into cups. The chilled water system is like the cups and the straws. The cups hold the chilled water, and the straws allow you to drink it. In the same way, the chiller chills the water, and the chilled water system circulates the chilled water to where it is needed.

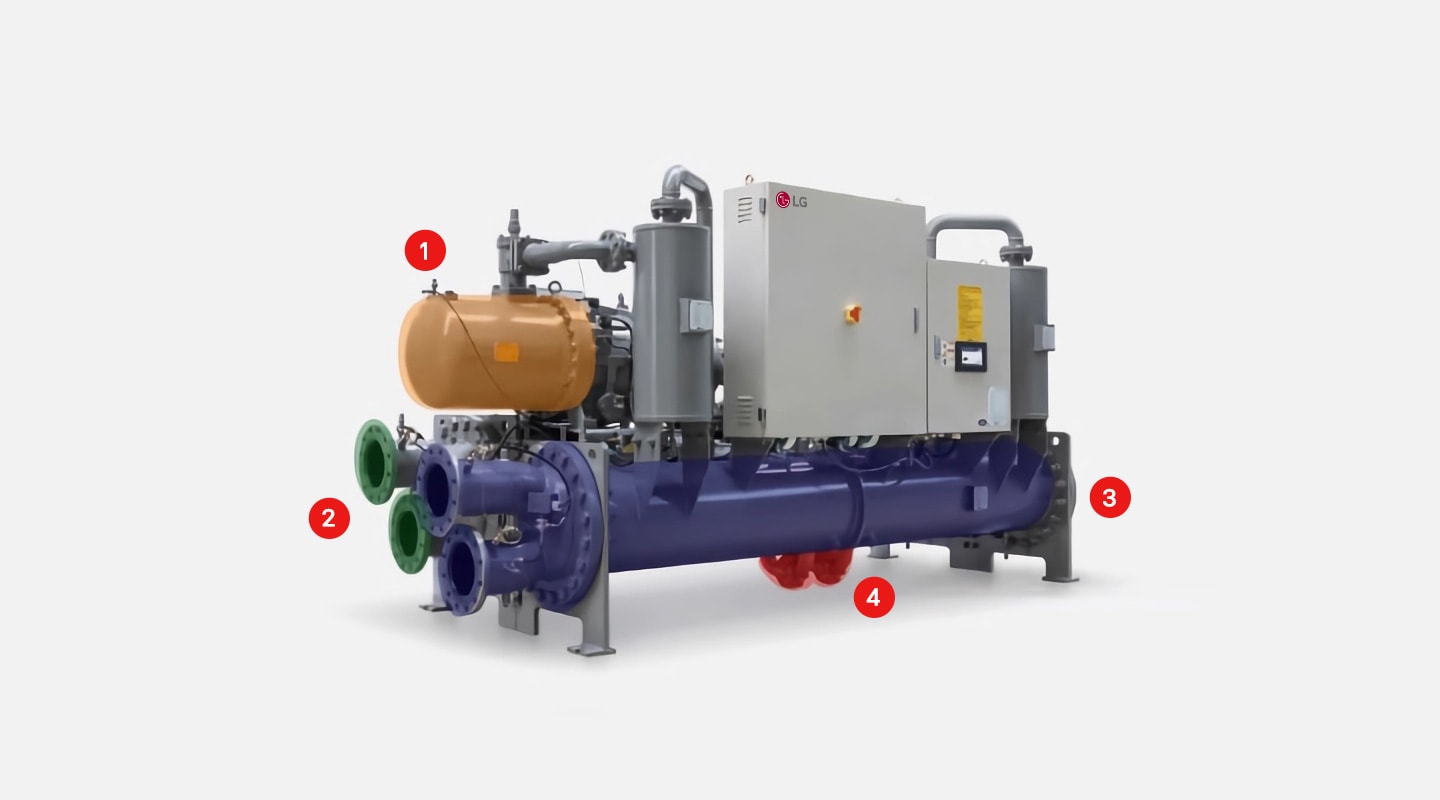

Types of Chillers and Their Components

There are different types of chillers available and each type of chiller has its own unique properties and functionality. Each chiller type is tailored to specific needs, offering a range of cooling solutions to cater to various applications and environments.

Centrifugal Chiller

-Utilizes the centrifugal force generated by a spinning impeller to compress the refrigerant

- Ideal for large cooling applications due to its high capacity

Centrifugal Chiller

-Utilizes the centrifugal force generated by a spinning impeller to compress the refrigerant

- Ideal for large cooling applications due to its high capacity

Absorption Chiller

- Use heat to drive the refrigeration cyde

- Energy-efficient, eco-conscious

- Types: Direct fired, Hot Water, Steam and Multi Heat Source

Benefits of chilled water systems

A. Energy efficiency

Chilled water systems are a very efficient way to cool large spaces. They can save significant energy costs compared to other cooling systems, such as direct expansion systems.

B. Scalability

Chilled water systems can be scaled to meet the needs of buildings and facilities of all sizes. They can be easily expanded or downsized as needed.

C. Zoning

Chilled water systems can be scaled to meet the needs of buildings and facilities of all sizes. They can be easily expanded or downsized as needed.

D. Reduced maintenance requirements

Chilled water systems typically require less maintenance than other cooling systems. This can save money and time over the life of the system.

E. Suitability of chilled water systems:

The suitability of a chilled water system for a specific application depends on factors like the cooling load, local climate conditions, budget, and energy efficiency goals. It is important to consult with HVAC professionals or engineers to determine the most appropriate cooling solution for a particular building or facility.

Types of buildings and facilities where chilled water systems are commonly used?

Chilled water systems are a versatile and efficient cooling solution for a wide range of commercial, industrial, and institutional buildings and facilities. They offer precise temperature control, energy efficiency, and the ability to serve large cooling loads.

Here are some of the types of buildings and facilities where chilled water systems are commonly used: Commercial office buildings, Hospitals & Healthcare facilities, shopping malls & retail centers, hotels & resorts, data centers and Manufacturing & Industrial facilities.

Contact Us

Please contact us for more information, and we will get in touch with you soon.