We use cookies, including cookies from third parties, to enhance your user experience and the effectiveness of our marketing activities. These cookies are performance, analytics and advertising cookies, please see our Privacy and Cookie policy for further information. If you agree to all of our cookies select “Accept all” or select “Cookie Settings” to see which cookies we use and choose which ones you would like to accept.

LG Electronics’ B2B heating, ventilation and air conditioning (HVAC) business is experiencing solid growth, propelled by strong sales of the company’s chillers designed for large buildings and commercial facilities. Leveraging LG’s differentiated core technologies, these solutions have seen an impressive surge in average annual sales with a nearly 40 percent increase over the past three years.

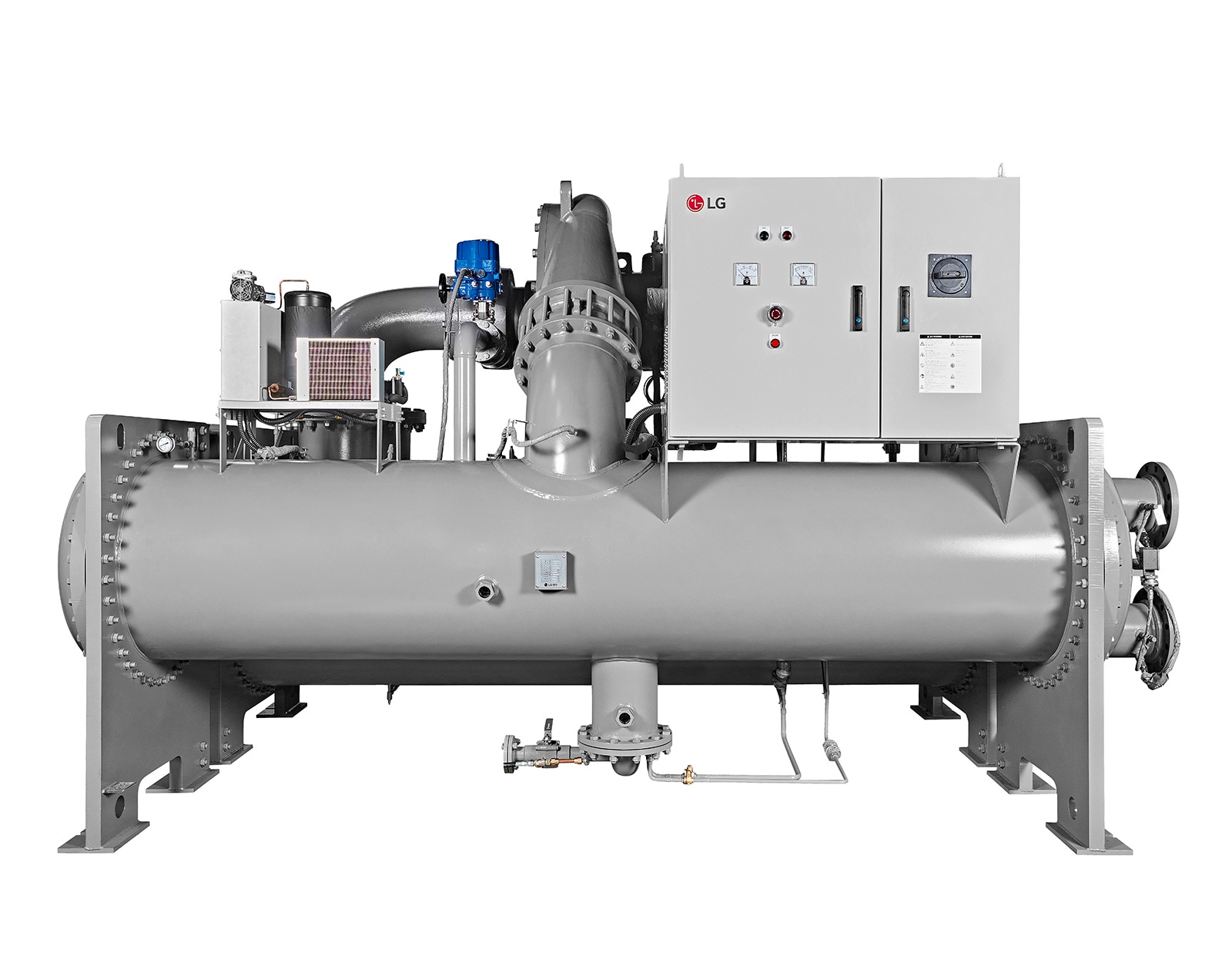

Chillers, cooling systems that supply cool air to indoor spaces by circulating cold water through a heat exchanger, have been a part of LG’s offerings since 2011. LG now boasts a full lineup of HVAC solutions, including residential and commercial air conditioners, central air conditioning chillers, chillers for nuclear power plants, and building management systems (BMS).

The HVAC business, emerging as a new growth engine for the company, is actively driving global sales of LG chillers. This is accomplished by targeting not only new battery and material manufacturing plants but also established facilities like nuclear power plants. Recently, LG secured a significant contract to supply chillers for a state-of-the-art battery plant being built in North America.

According to LG’s market research, the global chiller market is anticipated to grow by six percent annually until 2027. LG's goal is to more than double its HVAC product sales by 2030, positioning itself as a top-tier global provider of both residential and commercial HVAC solutions, both of which continue to play a crucial role in LG’s B2B sector success. Commercial chillers are expected to make a meaningful contribution to the expansion of LG’s HVAC business.

LG chillers, equipped with an array of innovative technologies, offer not only great performance and energy efficiency but are also cost-effective in terms of maintenance. By integrating advanced heat pump technology and employing high-efficiency compressors and heat exchangers, LG’s advanced chillers provide reduced energy consumption and operational expenses compared to conventional chiller products.1

The LG Inverter Scroll Chiller, one of LG’s notable chillers, is an efficient heat pump system that supplies water and provides heating and cooling for commercial facilities. It utilizes R32 refrigerant, which boasts a global warming potential (GWP) only a third to a quarter of that of R410 refrigerant. Designed with easy maintenance in mind, LG chillers feature a number of simple-to-replace components and offer convenient access to streamline the inspection process.

Already well-established in Asia, LG’s chiller business is expanding internationally, increasing its presence in the Middle East, Europe and Central and South America in response to rising demand. The company has an advantage in the HVAC industry thanks to its sophisticated core technologies, which include key components such as compressors and motors. Additionally, LG is proactively investing in research and development, with a focus on essential HVAC technologies including heat exchangers, inverters and heat pumps.

“We are committed to delivering efficient cooling systems that leverage our proprietary HVAC technologies to present exceptional performance and value to our global customers,” said James Lee, head of the Air Solution Business Unit at LG Electronics Home Appliance & Air Solution Company. “LG will continue to expand its presence in the global HVAC market with differentiated solutions including chillers, aligned with the latest trends in electrification and decarbonization.”

1 Compared to previous 1-stage LG chillers, LG chillers adopt magnetic/air bearings (oil-free) with VSD drive, customized impeller and falling-film heat exchanger with high efficiency, increasing non-standard part load efficiency (NPLV) up to 91 percent based on GB Standard Condition, 500RT. Employing oil-free technology and fewer moving parts has helped reducing the operation cost of LG chillers up to 36 percent.

Contact Us

Please contact us for more information, and we will get in touch with you soon.