Animation description : What Is DVLED?

Animation description : What Is DVLED?

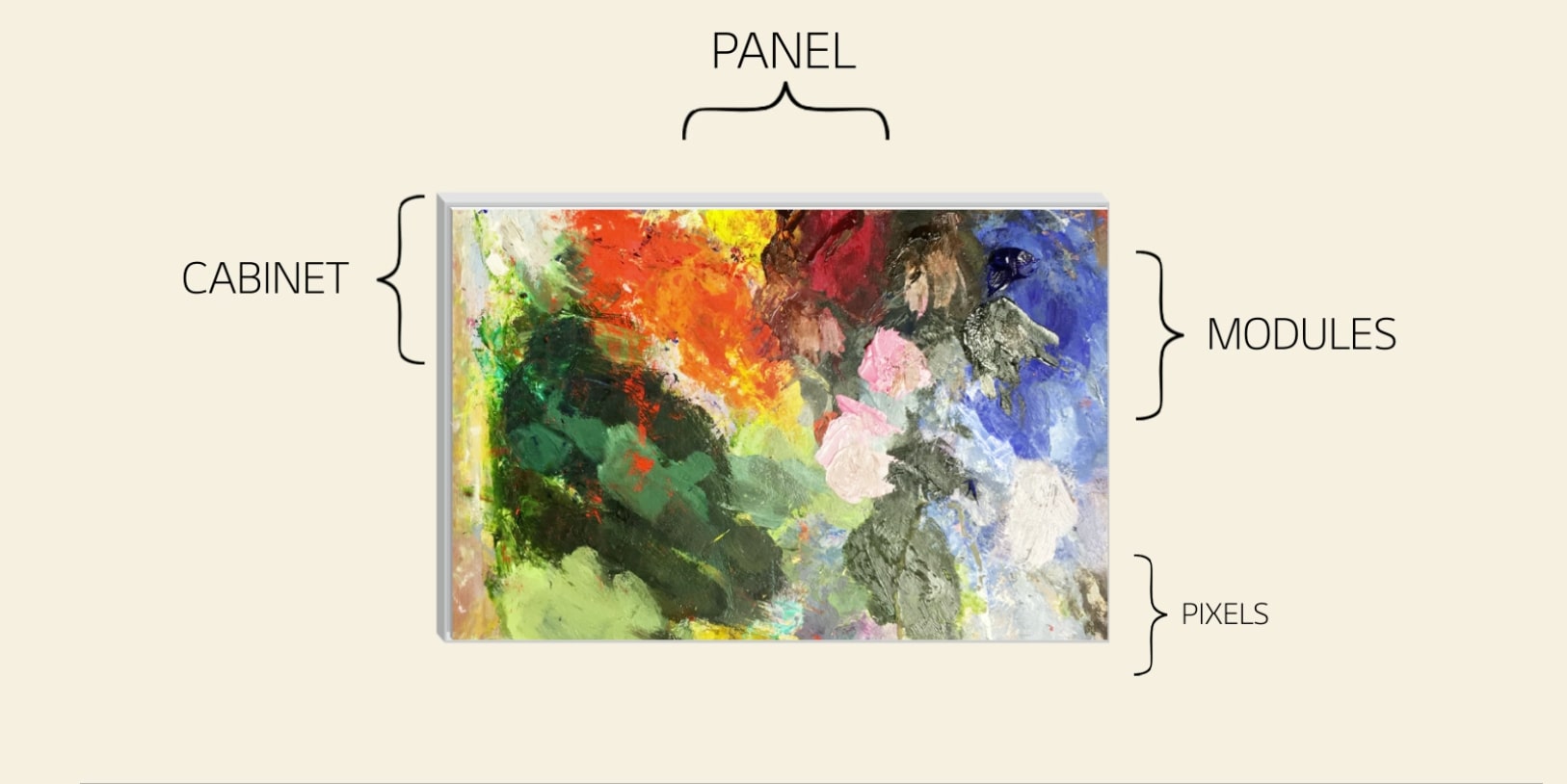

What is DVLED?

Direct View LED is not like regular LED - or any other display!

Direct View LED displays eliminate the LCD panel, instead using a surface array of LEDs as the actual display pixels. This allows for incredible contrast, vibrant colors, and brightness levels several times that of LCDs. Direct View LED displays can also be made virtually any size, including large sizes of 100 feet or more, making them the perfect choice for outdoor and indoor spaces alike. Thanks to the bezel-free design of Direct View LED displays, it’s possible to create seamless video walls too.

Your only limit is your imagination.

Liquid Crystal Displays Versus Direct View LED Displays

Liquid Crystal Displays Versus Direct View LED Displays

In contrast, Direct View LED (DVLED) panels do not need backlights, edge lights, and a shutter. The LEDs directly light the display without the need for a filter. DVLEDs panels are lighter, last longer, and emit less heat than LCD panels.

Common Anodes Vs Common Cathodes

Main Pixel Technologies

Pixels are an important force behind displays, and pixel technology has evolved significantly over the years. LG has solutions to best suit your DVLED display needs, utilizing a variety of pixel types. Which pixel is best depends on the intended purpose of the display, such as viewing angles, durability, contrast, ease of service, whether the display will be installed

indoors or outdoors, and other factors.

Chip on Board (COB) pixels are constructed with the color chips mounted directly on the printed circuit board (PCB), allowing for tight pixel pitch, contrast, viewing angles and great color. Due to the layering techniques used on the surface of these pixels, COB pixels are very durable. COB pixels are suitable for indoor displays where the audience will be closer to the screen, such as wayfinding displays, advertisements, or menu boards.

Integrated Matrix Device, or 4-in-1 Surface Mount Diode, (IMD) pixels are similar to the Surface Mount Diode (SMD; see below) but have four times as many pixels per module. SMD becomes fragile at tight pixel-pitch, creating an increased risk of damage at tighter pitches. With IMD-style pixels, fine pitch displays are less vulnerable to physical impact, excessive heat, and other environmental issues.

Surface Mount Diode (SMD) pixels are composed of modularly packaged color mounted directly on the PCB surface, hence the name. These pixels are suitable for indoor or outdoor use; most LED screens are composed of SMD pixels. Globally, SMD pixels make up the vast majority of indoor DVLED displays.

Dots in Place (DIP) pixels are often composed of three colored dots mounted in the middle of the pixel. DIP pixels are coarse and bright, and are best for large-scale outdoor displays such as scoreboard, billboards, or other displays where the audience is much further from the display.

DVLED Technology

Efficient display technology and durable pixel type are a big part of the DVLED module, but attaining the right specs such as pixel pitch, brightness, and IP rating can make the DVLED display more powerful.

Animation description : DVLED Technology

Animation description : DVLED Technology

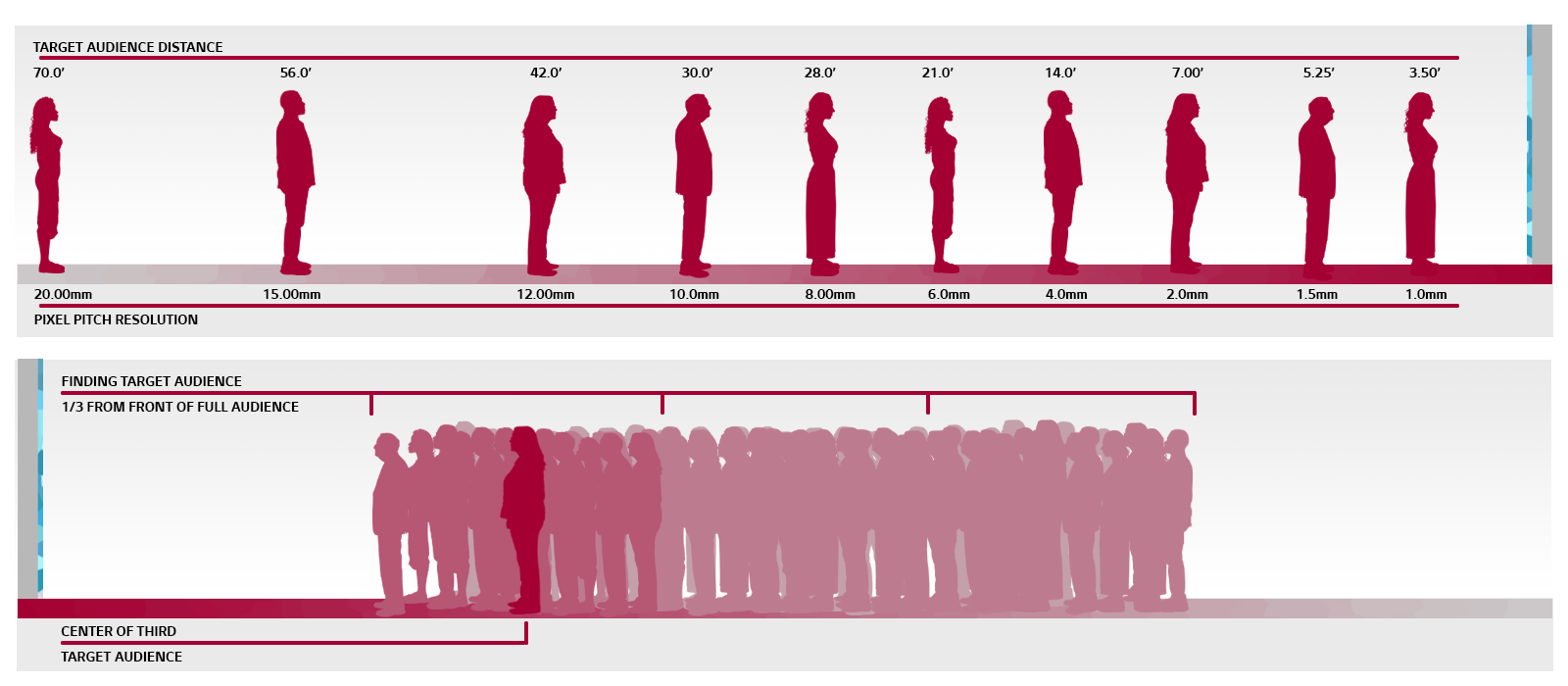

Pixel Pitch is Dependent on the Space and Audience

Graphic description : Pixel Pitch is Dependent on the Space and Audience

Graphic description : Pixel Pitch is Dependent on the Space and Audience

Tight Pitch

Graphic description : Pixel Pitch is Dependent on the Space and Audience

Graphic description : Pixel Pitch is Dependent on the Space and Audience

Wide Pitch

Graphic description : Pixel Pitch is Dependent on the Space and Audience

Graphic description : Pixel Pitch is Dependent on the Space and Audience

Tight Pitch

Graphic description : Pixel Pitch is Dependent on the Space and Audience

Graphic description : Pixel Pitch is Dependent on the Space and Audience

Wide Pitch

Save with Energy Efficient DVLED

Save with Energy Efficient DVLED

-

Save with Energy Efficient DVLED

Save with Energy Efficient DVLED

Common-cathode LED uses the exact power needed for each subpixel, reducing power consumption and heat compared to conventional direct-view pixel technologies. -

Low Display Heat Reduces Wasted Energy

Low Display Heat Reduces Wasted Energy

Heat is measured by BTUs. The less power efficiency, the higher the operating expenses, and the higher the HVAC expenses. -

The Right Brightness can Save Costs

The Right Brightness can Save Costs

Brightness is measured by nits. Like the top speed of a car, you don’t always use the max brightness. The nits needed depend on the space of the DVLED. -

IP Ratings Show Ingress Protection

IP Ratings Show Ingress Protection

The two numbers on an IP rating represent dry particle defense and moisture defense. The higher, the better defense! This is important for outdoor displays.

Save with Energy Efficient DVLED

Low Display Heat Reduces Wasted Energy

The Right Brightness can Save Costs

IP Ratings Show Ingress Protection

-

Graphic description : True Curve Displays

True Curve Displays

LG’s curved DVLED displays are true curves - not just faceted like other displays, but smooth-flowing around corners, walls, and other curved spaces for stunningly fluid imagery.

-

Graphic description : Transparent Displays

Transparent Displays

LG’s transparent DVLED displays have a variety of uses. Trimmable film means transparent DVLEDs can be custom fit to any space, creating dynamic displays in windows, transparent walls, and other locations.

DVLED Controller Offers Complete & Easy Access

DVLED Controller Offers Complete & Easy Access

-

Mount Installation*

The first step is to install the mounts and cabinets, and conduct cable and signal tests. It’s important for mounting to be installed correctly, since it’s the foundation for the rest of the display.

-

Module Installation

Next the modules are put into place. Modules will light up with test visuals as they’re installed. Color and pixel calibration is done in-factory, so all that’s next is configuring the display layout.

-

Fully Installed

With installation completed, the display is ready to go!

Installation & Mounting Partners

Mounting fine-pitch DVLED is a highly sensitive and critical operation. While it’s possible to be successful with a generic mount, the precision required means costly mistakes are more common. For deeper assurance of secure mounting, LG, your value-add partner, has chosen to give you the best mount opportunities by partnering with these trusted mount & accessory experts:

All-in-One DVLED Displays

All-in-One DVLED Displays

Easy Installation in Half a Day**

**Statement based on previously documented successful installations. Actual time may vary based on installer.

Screen images are simulated and are for example purposes only.